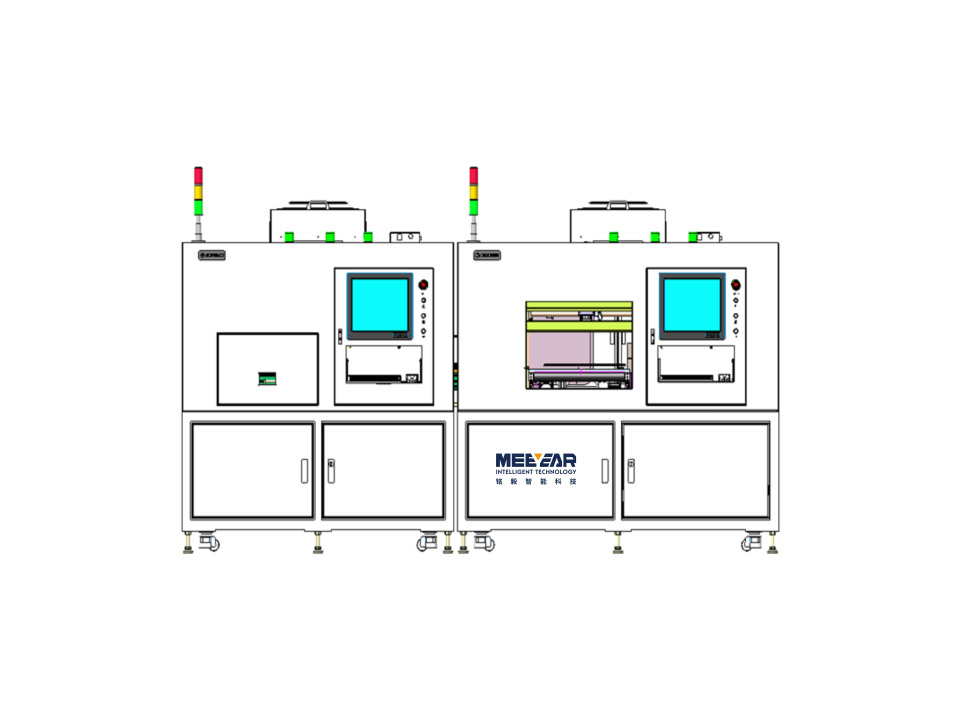

● Each station adopts automatic feeding system;

● The intelligent imaging system detects the assembly size and appearance of the product;

● Optical fiber type laser coding machine to code good products;

● The type of product assembly can be switched arbitrarily (up to 9 types), and the production process is unmanned.

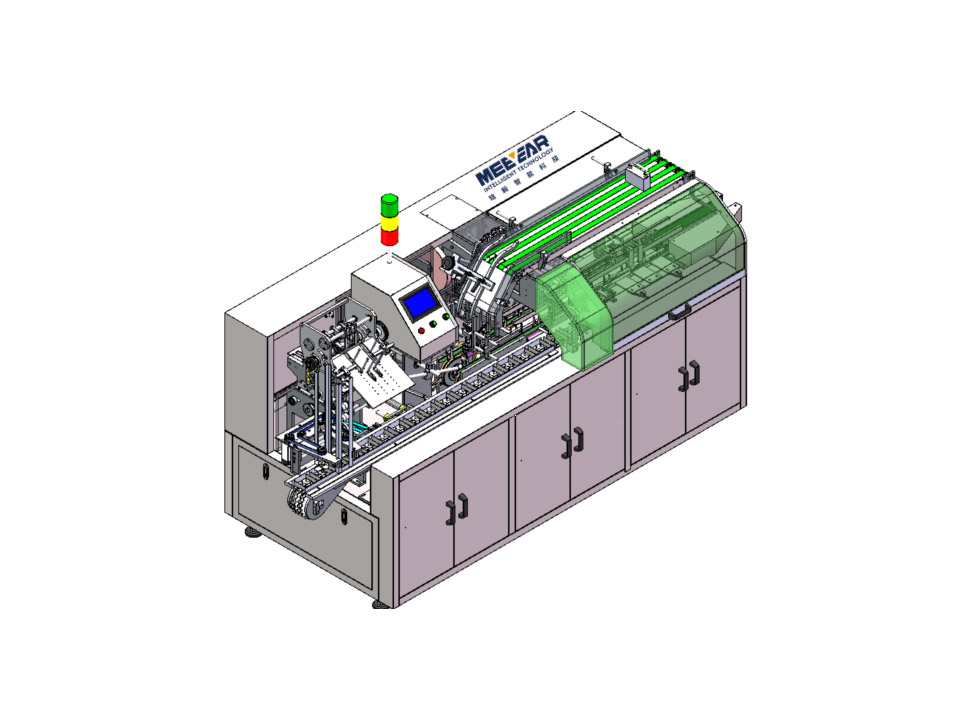

● The pin adopts a high-speed cam mechanism and is driven by a servo motor, which can ensure high-speed, high-precision and stable pin;

● The bending module is driven by a servo motor, and the bending parameters are easy to set and operate, and the bending accuracy and angle can be better guaranteed;

● Clean the product through brush and suction mechanism;

● Adopt electric Gauge and CCD for position and height detection, with performance tests such as conduction and high voltage.

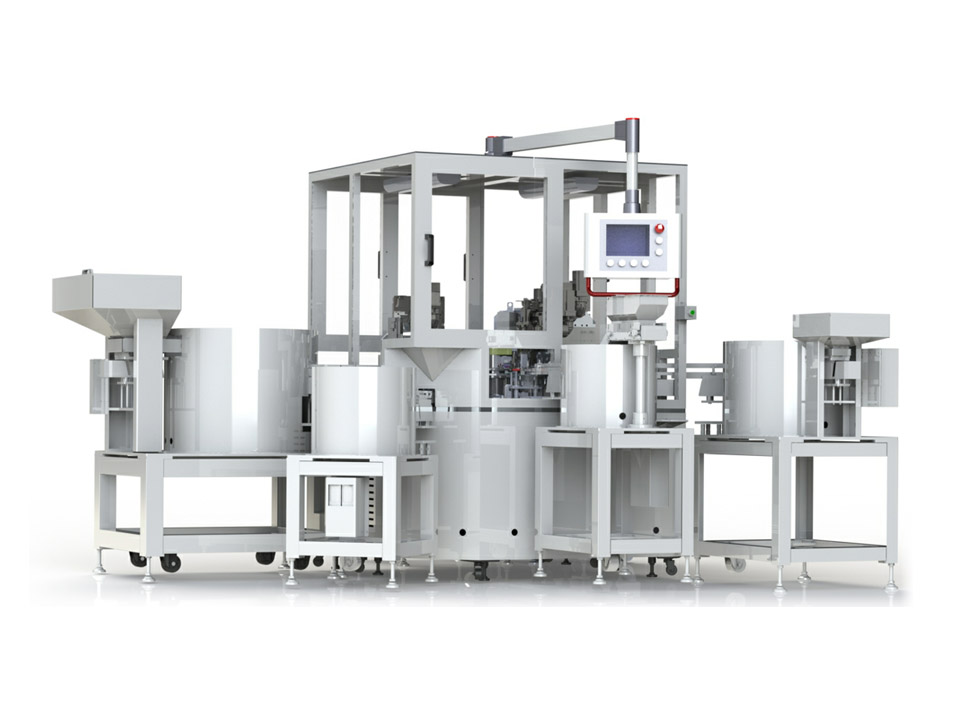

● The equipment shown is a vertical cam pin machine

● High-speed vertical cam mechanism: high speed, high precision and stability

● Electric Gauge and CCD test: high performance

● Automatic packaging: final inspection, counting, packaging

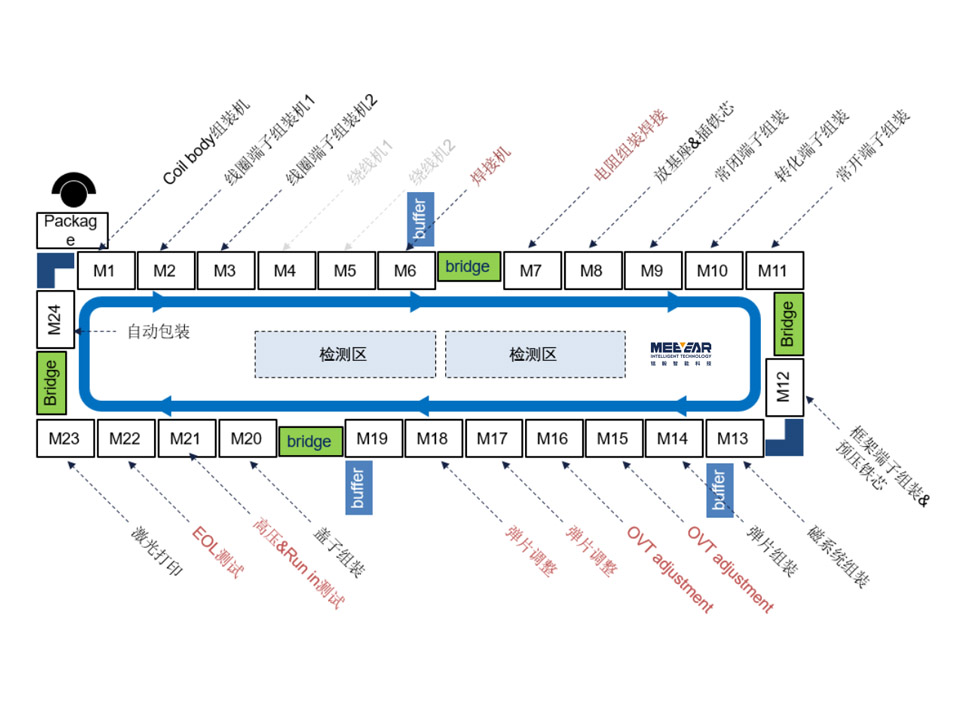

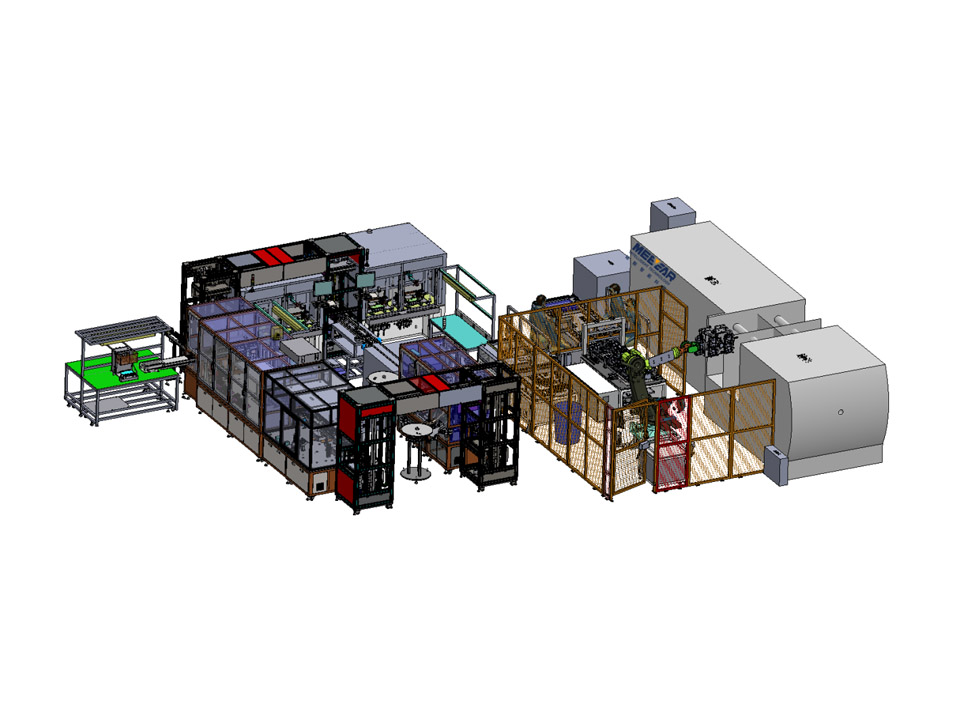

● The reflow carrier is transplanted cyclically in the loop body. After the empty carrier is picked up and packaged by the last packaging machine, the empty carrier is returned to the first equipment

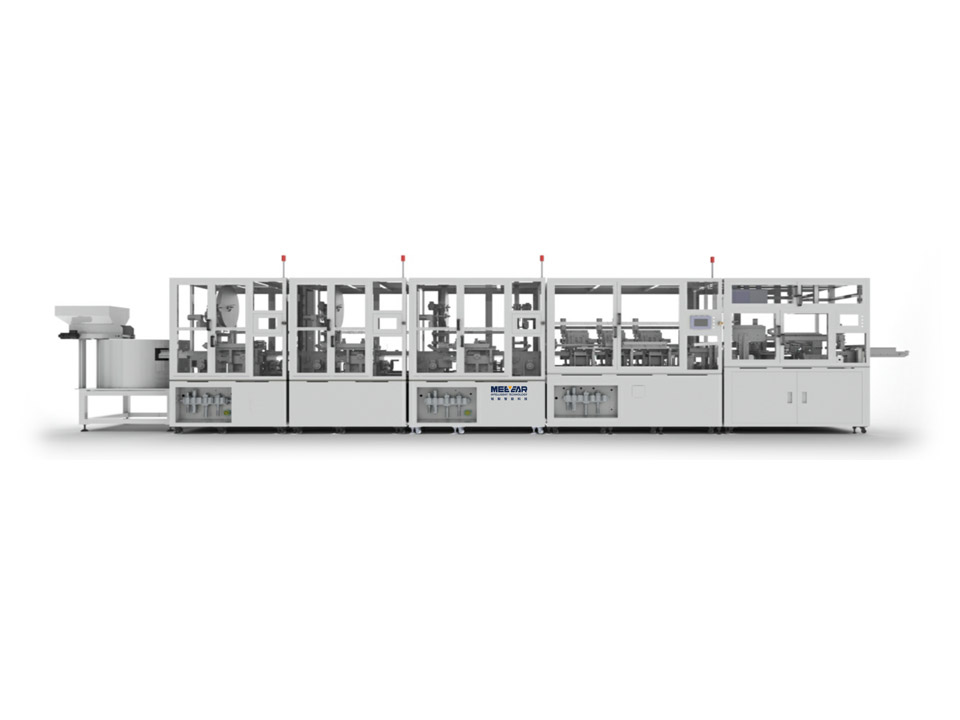

● Automatic feeding of product parts to realize automatic winding, assembly, OVT adjustment, shrapnel adjustment, detection, coding, and packaging

● The production/test data of the whole line can be queried and traced

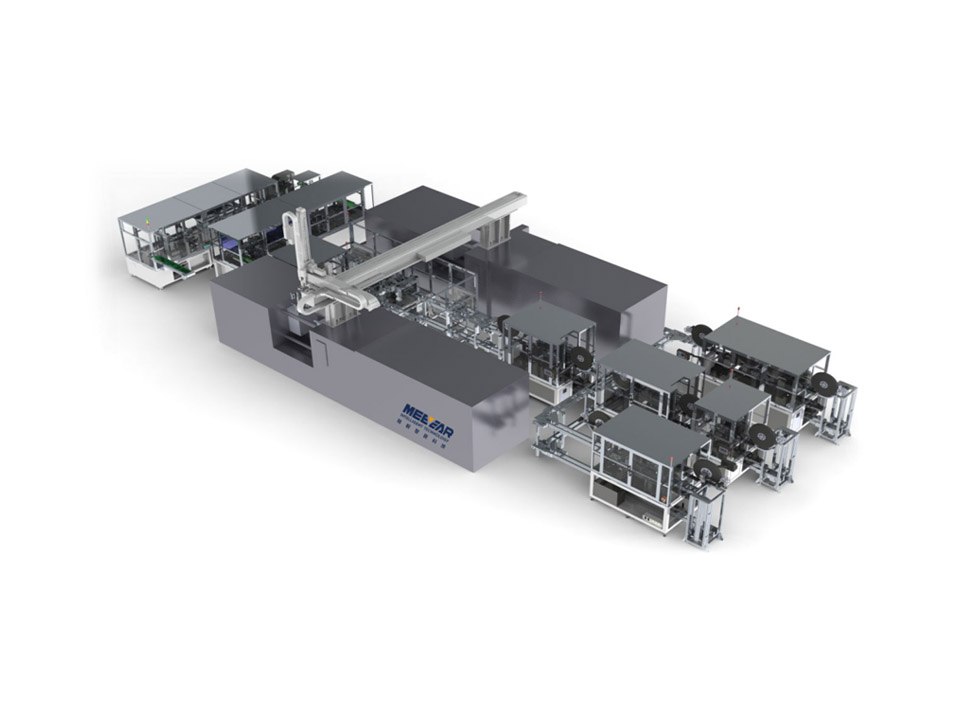

● 6-axis and WITTMANN manipulators are used for transportation before and after molding. The manipulator palm design adopts flexible and high-precision positioning and automatic correction mechanism to ensure the accuracy of injection molding and rapid product change;

● WITTMANN robot handles both loading and unloading of two injection molding machines;

● The production/test data of the whole line can be consulted and traced.

● Professional forming, pin, welding, software customized testing solutions

● Streamline operation, full station retrospective upload system

● Manipulator fast switching

● Process and software function module customization

● This equipment is an automatic peeling and tinting machine

● Contains functions: wire harness cutting, zero cutting, coaxial machine peeling, automatic soldering and tinting, etc.

● High degree of automation, which greatly improves production efficiency

● Using automatic opening (suction) box, folding instructions, unloading, feeding, batch number, sealing, stable operation, low noise

● The automatic shutdown function of mechanical overload is adopted to ensure the safety of man and machine

● Incoming line, servo stack tray, control tray cover rubber band; servo control sucks PC bag, cylinder assists to open the bag

● The air cylinder sends the tray into the PC bag, and the bag is sealed and vacuumed

● The pin adopts an electronic cam mechanism and is driven by a servo motor, which can ensure high-speed, high-precision and stable pin

● The bending module is driven by a servo motor, the bending parameters are easy to set and operate, and the bending accuracy and angle can be better guaranteed