● 6-axis and WITTMANN manipulators are used for transportation before and after molding. The manipulator palm design adopts flexible and high-precision positioning and automatic correction mechanism to ensure the accuracy of injection molding and rapid product change;

● WITTMANN robot handles both loading and unloading of two injection molding machines;

● The production/test data of the whole line can be consulted and traced.

| Equipment reference size:

| Length 18 meters * width 7 meters * height 3 meters | Comprehensive equipment efficiency: | ≥ 85% |

| Cycle: | 24S/ 2PCS | Defect rate: | ≤0.5% |

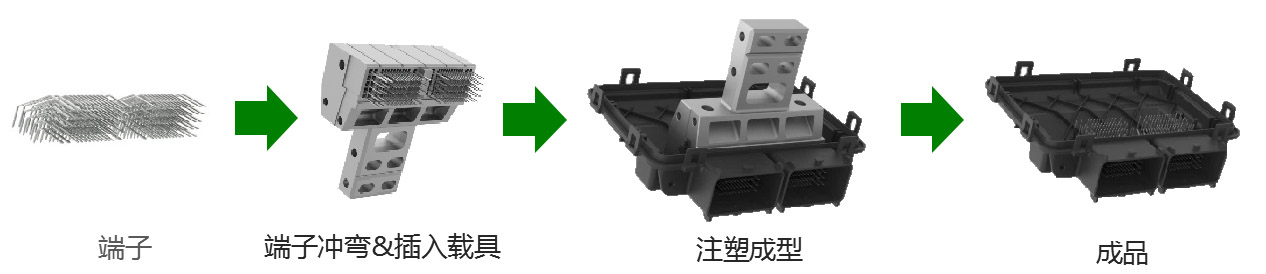

● Metal insert injection molding is a molding process in which metal special-shaped parts are placed in a mold and merged and solidified through injection molding to form an integrated product; different from the traditional separate assembly mode of metal and plastic parts, this method simplifies the production process. Improve the stability and reliability of the product;

● The insert injection molding process usually includes metal insert feeding, mold loading, injection molding, inspection and other processes. Among them, the process control and rhythm coordination of injection molding are very important.