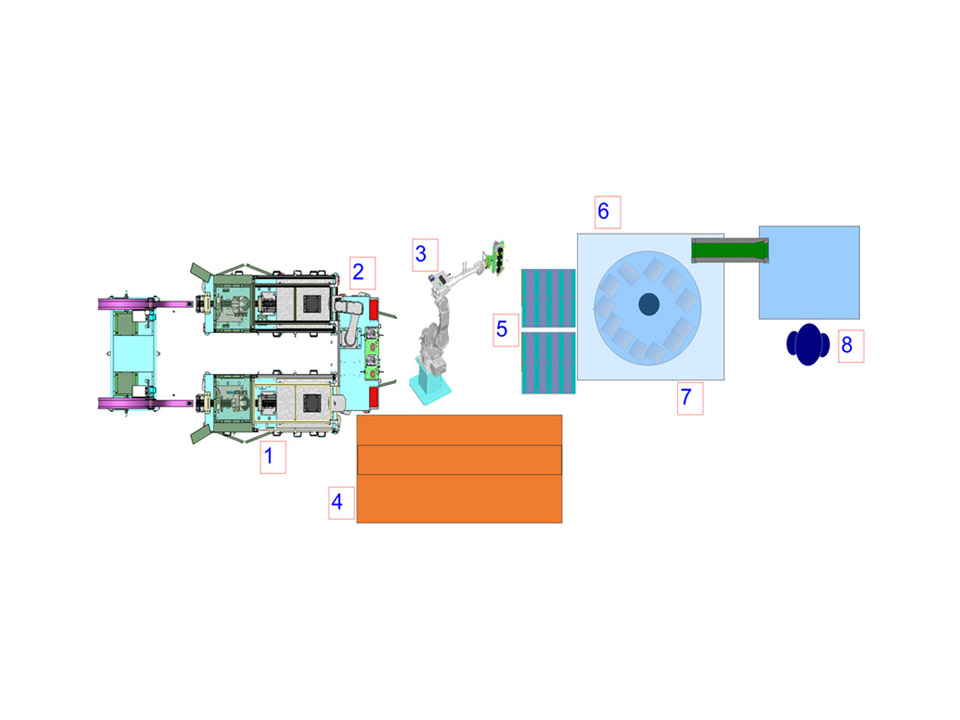

● Fully automatic production line includes: terminal incoming CCD detection, material head welding, stamping and cutting, CCD detection, NG product counting+, injection molding, finished product size detection, performance testing, NG product cutting, strip welding, counting and receiving Material and automatic change of trays realize fully automatic and unmanned operation, effectively control product quality, and submit production efficiency.

● Up to one mold with 16 holes

● The perfect combination of automation, stamping and injection molding

● Fully automatic Cover production line, including terminal bending and cutting, C inspection, automatic terminal insertion, injection molding, product online inspection, and realize full automation

● Standardized design

● Quick replacement

● Cylinder clamping and ratchet feeding

● CT<=28S

● One mold with four holes

● The perfect combination of automation, stamping and injection molding