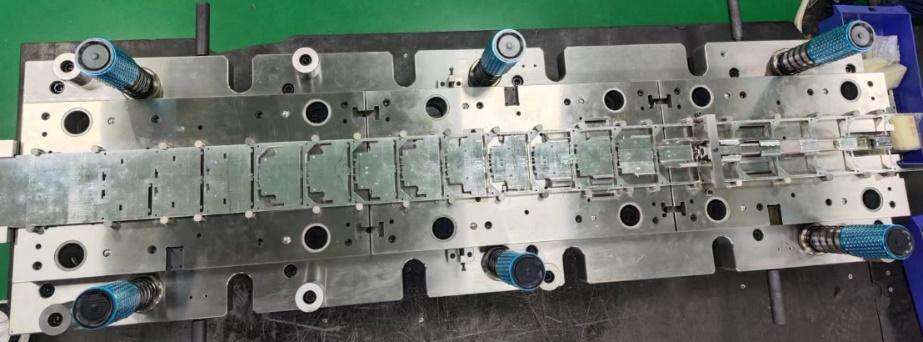

-Tooling type: Conventional 3-plate

-Tooling parameter: 1Row * 1Feed

-Stamping/punching speed: 35 SPM

Technicial Highlights:

-Complex forming

-High precision requirment

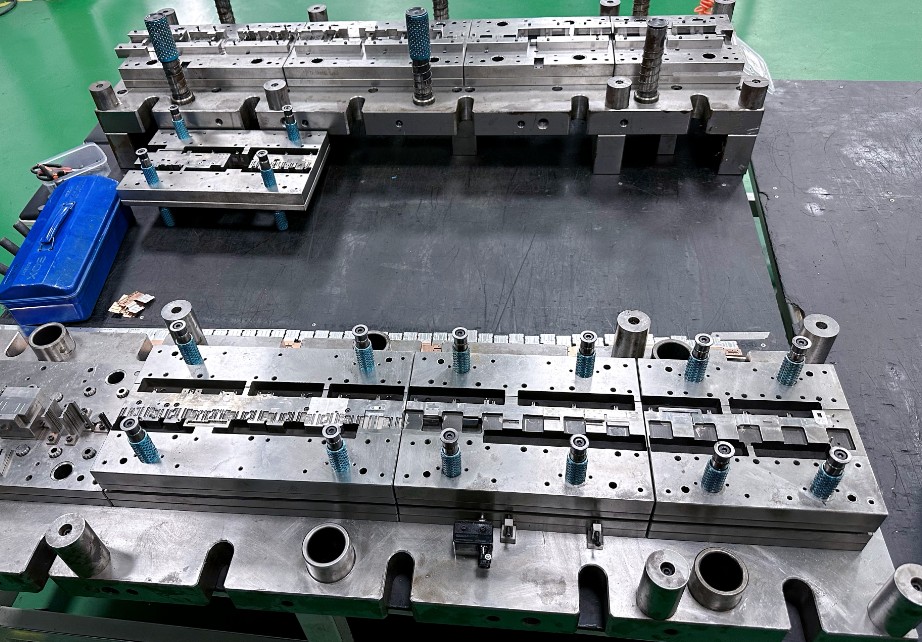

-Tooling type:Conversional 8 plate tooling

-Tooling parameter:1Row * 1Feed

-Stamping/punching speed: 40 SPM

Technicial Highlights:

-Quick change-over module

-Online adjustment

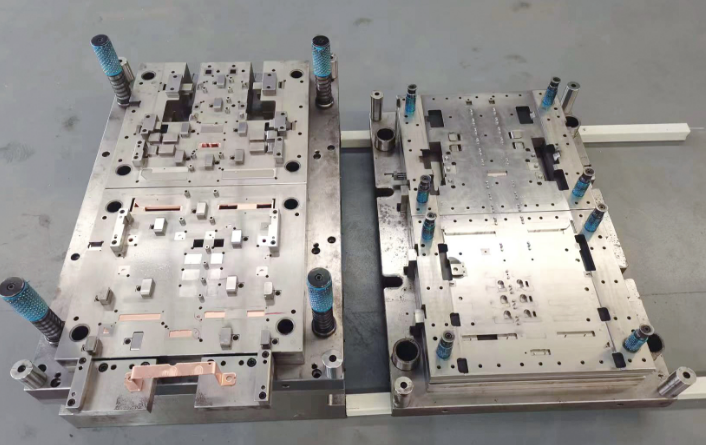

-Mold Type: Conventional 8-Plate Mold

-Die output rate: one out of one

-Stamping speed: 40 SPM

Technical Highlights.

-Complicated molding is possible

-High precision requirements can be met

-Type of mold: Conventional 8-plate mold

-Die output rate: one out of one

-Stamping speed: 30 SPM

Process technology highlights: -Complicated molding possible -On-line adjustment

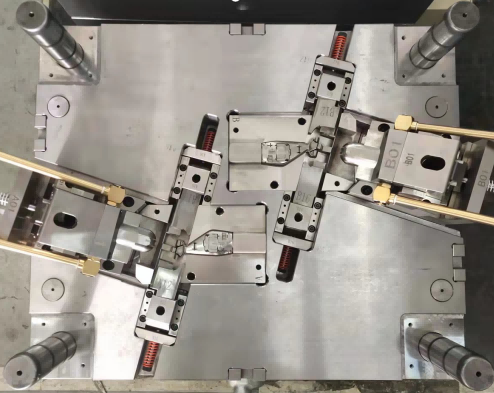

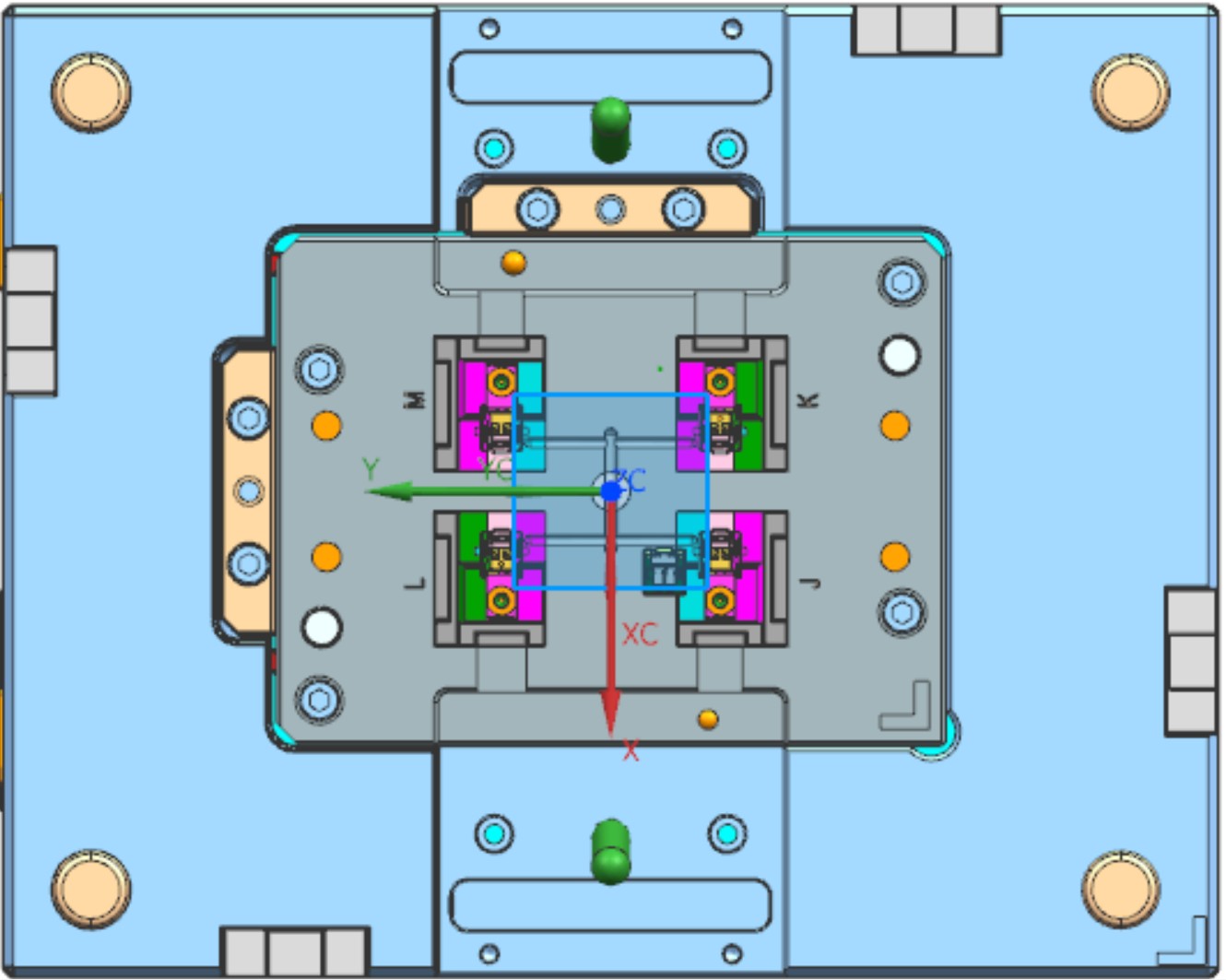

-Tooling type:3 – plate with hot runner system

-Tooling parameter:2 cavity

-Cycle time: 18.5 sec/shot

-Material: PA66+65% GF

Technicial Highlights:

-Multi-angle slider design

-High strength fiberglass material used

-Low maintenance cost due to coating treatment technology used

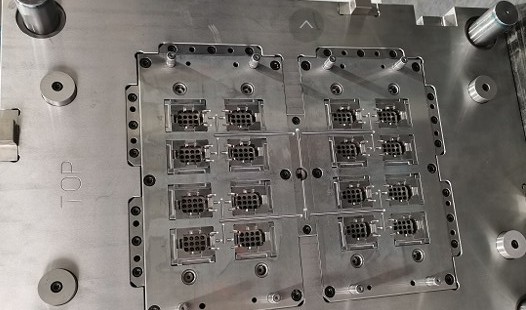

-Tooling type:3 – plate

-Tooling parameter:16 cavity

-Cycle time: 21.0 sec/shot

-Material: PA66+30 %GF

Technicial Highlights:

-Melt flipper technology

-Slider in female side , Double ejection mechanism in male side

-Stabilized process due to pressure sensors used

Process technology highlights:

-Using runner flip technology, product quality is stable and reliable

-Use of in-mold pressure sensors to ensure the stability of the process.